Component cleaning

Off-highway haulage truck maker TerexTrucks has halved the time it takes to clean vehicle components by employing ultrasonic cleaning technology from British company Ultrawave.

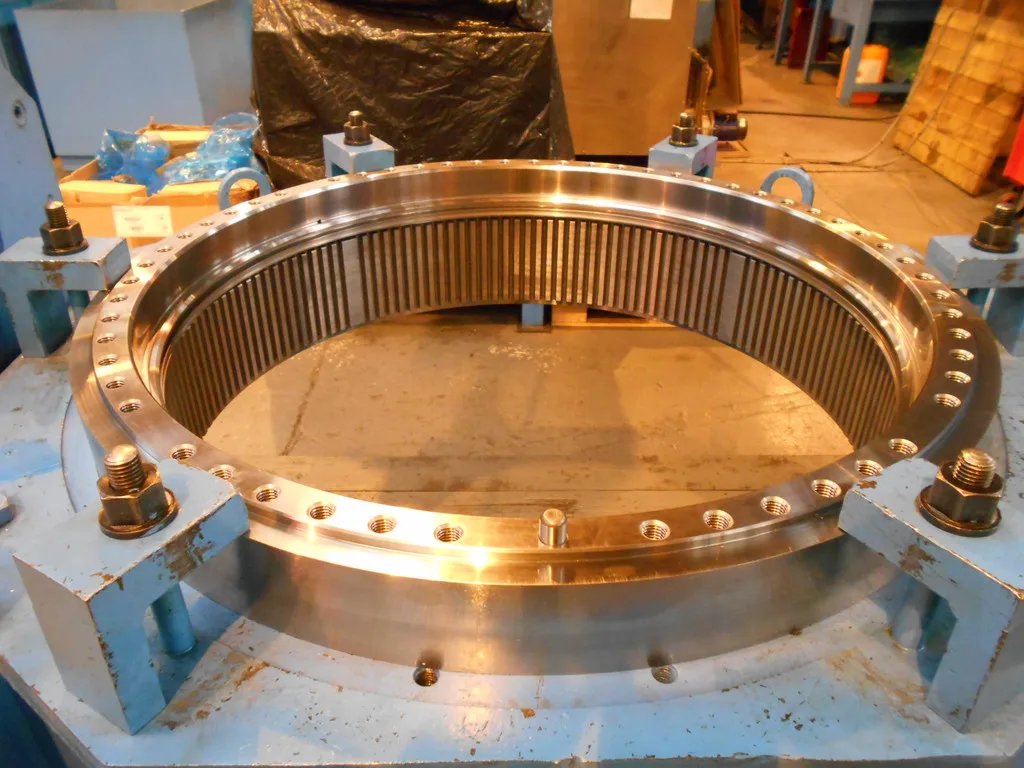

Rotary spray washers were previously used during the manufacturing process but whilst they cleaned the external surface of components, they did not remove oil and casting residue from the intricate and detailed component design. High cleanliness levels are essential as parts can be damaged, causing rejects, if any contamination remains.

Ultrawave recommended a single, heavy duty ultrasonic cleaning system to replace the three rotary washers. The 615 litre ultrasonic cleaner included a heavy duty basket to support the parts weighing up to 150Kg. Incorporating a built-in stainless steel pump and filtration system with a hinged lid, ultrasonic cleaning is provided by submersible transducers for ease of service.

Having commissioned the new cleaner, Terex Trucks started to make savings on their previous contract costs which reached tens of thousands per year. The cleaning cycle time has also been cut in half, with a full load now processed in just 8 minutes.

HSM publishes a weekly eNewsletter, delivering a carefully chosen selection of the latest stories straight to your inbox.

Subscribe here